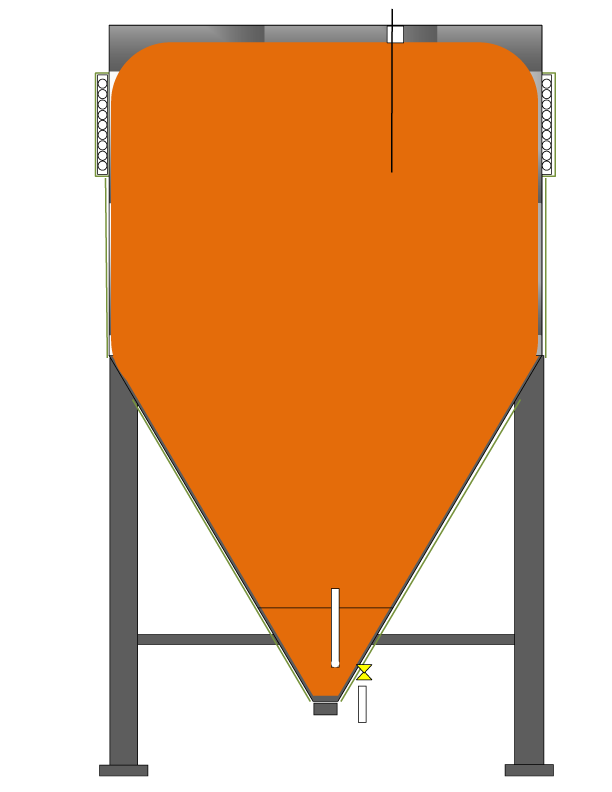

The SURF is a sanitary fermentation liner fabricated from food grade hydrocarbons which holds the fermenting beer in the same way as a unitank.

However this flexible container is used just once, when the fermentation/conditioning process is complete the empty container is folded up and sent for recycling.

The SURF is a liner sits inside a rigid container in the shape of a unitank to maintain structural integrity of the liner. The rigid container is called a “SURF Shell” which is configured with cooling jacket for the purpose of temperature control.

Sturdy & stable steel sheel construction

Top adaptor with Thermowell & vent pipe

High efficiency cooling element

Easily removable bottom cone fitted with toggle clamps for SURF liner installation & removal

Adjustable feet for balancing

Pipe-in pipe bottom adaptor for separation of beer and yeast. Also SURF low point drain

Steep angle to allow for cold break and yeast collection in cone

High efficiency insulation

Multi-Function Sanitary Design Nozzles

The standard SURF is configured with a top and bottom sanitary design nozzle into which specially designed stainless steel adapters are placed. A pipe-in-pipe adaptor is secured in the bottom nozzle which facilitates filling, sampling, beer racking and yeast collection. The adaptor secured to the top nozzle contains the thermowell and a vent tube.

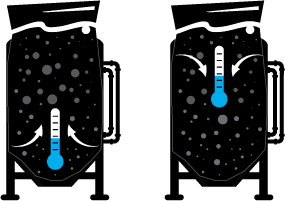

Temperature Control

A temperature sensor is installed in a thermowell which is inserted into the SURF via a top nozzle and secured in place with a clamp. Any control system can be used to monitor and control the fermentation temperature by actuating an automated valves on the SURF cooling jacket inlet. Standard temp control functionality achievable with this system e.g. crash cooling, temp gradient, etc.

Customisation

Cooling jacket on SURF Shell cylinder can be positioned as per brewer operating volume requirements. Alternatively two cooling jackets can be fitted. The brewer is also free to fabricate their own SURF shell.

In-Line Carbonation

Eliminate the need for forced carbonation by utilizing in-line carbonation technology. Small carbonators are available for direct in-line carbonation on beer coming from SURF. Also possible to in-line carbonate beer during filling to bottles/cans.

ADVANTAGES

OF THE SURF TECHNOLOGY

Environmentally friendly beer fermentation process which is significantly cheaper than traditional stainless steel vessel technology. Ideal for start-up microbrewers, brewpubs and rapid expansion of existing facilities.

Facilitates all standard fermentation functionality

including yeast collection for repitching, racking of beer, temperature control, etc.

Uses Safe food Grade polymers

With no leachables or extractibles.

Eliminates the need for any stainless steel pressurized vessel

By utilizing in-line carbonator for CO2 addition during transfer to tap/filling.

SURF significantly reduces your

Water Usage

No water required for fermenter cleaning, rinsing and sanitization. Chemical Usage – No cleaning or sanitizing chemicals required.

Energy Usage

No heating of cleaning solutions or rinse water.

Capital Cost Investment

No high specification pressure rated vessels

Labour Requirements

Eliminate time and resources required for fermenter cleaning.

Beer Quality

Reduce risk of beer contamination by utilizing sanitary liners.

Overall Carbon Footprint

SURF is more environmentally friendly than the standard stainless steel unitank due to elimination of cleaning.